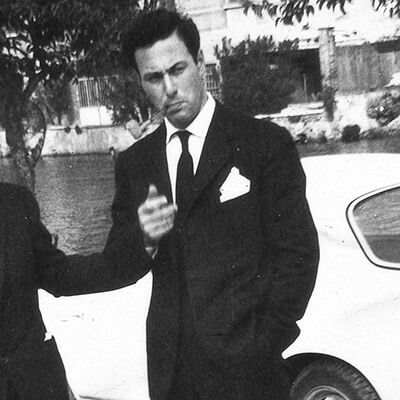

Lionello Maggi's intuition in 1963 gave rise to an entrepreneurial adventure that continues today, carried forward by the commitment and passion that we put into our work every day.

Lionello, a mechanic with design skills, decides to go into business for himself, by opening a small artisan workshop called "Maggi Costruzioni Meccaniche" and begins to design his first automatic power-feeding unit, since then over 500,000 of these devices have been produced for markets around the world.

After just six years, the small artisan business already has 10 employees and is going full steam ahead. The business moves to a more spacious location that can accommodate a larger workshop. The new line of automatic advancements is born under the "STEFF" brand, in homage to the names of Lionello's two children: Stefania and Stefano.

Lionello is able to establish long lasting business relationships worldwide. This attention to human relationships left an indelible mark on the company that, even today, is extremely attentive to the value of human relationships as the basis of business relations. Maggi develop the first radial saws of the RADIALSTEFF line, which, like the power-feeding units, quickly become a great success.

Maggi company participates for the first time, as a manufacturer of woodworking machines, at the most important international trade fair of the sector, the "LIGNA" in Hanover, Germany

Maggi company move to its current location, 5000 m2 on a 10,000 m2 surface area. All models of feeders and radial saws are renewed. The inclination towards international relations intensifies, so that the company acquire great experience in exporting, particularly to Europe and the USA, but also Australia and South Africa; Maggi products become competitive against the biggest market leaders.

Stefania Maggi, after completing her studies, joins her father in the company dedicating herself to the sales sector.

A 3-axis machining center is purchased for processing the automatic power-feeders, the pride of our production.

Maggi participates in the first trade fair in Singapore, a strategic hub for distribution across Southeast Asia. The following years see the most significant development in the USA, and the beginning of expansion into South America. First trip to Moscow to discover a new market that would bear its first fruits several years later.

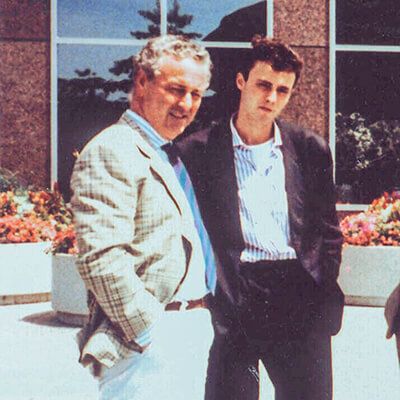

Lionello Maggi opens up to other partners who join the Board of Directors of the new company "Maggi Engineering". His son, Stefano Maggi, after completing his studies, begins working in the company alongside his sister, Stefania, and the other partners, Mr. Mauro Landi and Mrs. Lidia Gianni.

The first single-head boring machine with 22 spindles is born, it's the beginning of our journey in the drilling field.

2 numerical control machining centers are purchased to support the growing production needs.

Maggi obtains the prestigious German safety certification "GS" for STEFF automatic power-feeders, and the utility patent for the SEMI-HUB roller of the new STEFF 2033 model.

The "BORING SYSTEM" single-head boring-machine line is born: technically innovative, but also attentive to design and ergonomics.

A modern electrostatic powder coating system is purchased to improve product quality and achieve greater production flexibility.

The "BORING SYSTEM" drilling machine line becomes increasingly popular and appreciated, becoming the company's flagship product. In the early 2000s, the line was renewed in design and features, and the first multi-head models with 2, 3, and 5 drilling heads were created.

Giacomo Landi, son of Mauro Landi, a member of the board, joins the management team and begins by working in the sales department, to establish direct contact with customer needs, and then moves on to manage the Production and Service Dpt..

Deep restructuring and strong drive towards optimization of all business processes. At the "Ligna" fair in Hannover, the new BORING SYSTEM EVOLUTION drilling machine is presented: Maggi's first step into the world of CNC machines.

At the international LIGNA trade fair in Hannover (Germany), the entire Maggi staff, together with its founder, Lionello Maggi, celebrates the company's 50th anniversary in the presence of their dealers; on the same occasion, the company was awarded recognition by the LIGNA Fair organization as one of the historical exhibitors of this event.

Giulia Calamassi, daughter of Stefania Maggi and granddaughter of the founder, joins the company team and work alongside her mother within the sales department, primarily focusing on developing the Italian market.

Maggi inaugurates the new production line for the single-head drilling machines, inspired by the principles of Lean manufacturing philosophy: optimization, planning, and waste reduction; thus, increasing production capacity, ensuring reliable and quick deliveries to customers and further improving product quality; making them increasingly competitive in the global market.

During the long pandemic period, despite many difficulties, Maggi never stopped working on its projects, producing and serving its customers and standing by them, implementing a revolutionary APP to continue providing real-time online after-sales support.

Maggi continues its path of production optimization, inaugurating two new "Lean" production lines for power feeders and radial saws, and launches the new company website: a content platform serving customers and reflecting our commitment to simplify their life !

In the international setting of the XYLEXPO fair in Milan, Maggi presents the first electronic multi-spindle drilling machine CN 21 TECHNOLOGY, another Maggi patent, and the new user-friendly programming SOFTWARE for the BORING SYSTEM EVOLUTION line.

In May, during the international biennial woodworking machinery fair “LIGNA,” Maggi celebrated 60 years of activity with a special event dedicated to the business partners who have made this long journey possible. They will present the latest innovations from their continuously evolving range...